Views: 0 Author: Site Editor Publish Time: 2025-09-18 Origin: Site

You need reliable sharpening solutions for your woodworking business. Diamond stones sharpening offer superior hardness, fast cutting speed, and consistent flatness. You can sharpen tools quickly without oil or water, saving time and effort. These stones work for many tool types and last for decades. You gain efficiency and tool longevity, making them ideal for Industrial Applications of Diamond Stones Sharpening in Professional Settings.

Diamond honing stones offer faster sharpening, saving time and increasing productivity in woodworking.

These stones maintain a flat surface, ensuring consistent and precise sharpening without the need for frequent flattening.

Using water instead of oil for lubrication keeps the workspace cleaner and safer during the sharpening process.

Diamond stones last significantly longer than traditional stones, reducing replacement costs and downtime.

Selecting the right grit combination enhances sharpening efficiency, allowing for both quick material removal and fine polishing.

Regular maintenance, such as cleaning and proper storage, extends the lifespan of diamond sharpening stones.

Investing in diamond sharpening technology leads to long-term savings and improved tool performance in industrial settings.

Stropping tools after sharpening enhances edge quality, ensuring tools remain sharp and effective for longer periods.

You want your woodworking business to run efficiently. Diamond stones for sharpening give you a clear advantage in industrial settings. These stones use microscopic industrial diamonds, which are harder than any steel. This means you can sharpen even the toughest tool steels quickly and with less effort. Diamond machining technology sharpening stones also stay flat, so you get precise sharpening every time. You do not need to worry about uneven surfaces or frequent flattening.

Here is a quick look at the main advantages:

Advantage |

Description |

|---|---|

Fastest Cutting |

Diamond stones provide the quickest sharpening, essential for efficiency. |

Stay Flat |

They maintain a flat surface, ensuring precision in sharpening. |

Uses Water |

Water is a cleaner and more accessible medium for sharpening compared to oil. |

You can use water instead of oil, which keeps your workspace cleaner and safer. These features make diamond stones a smart choice for any woodworking business that values speed, accuracy, and cleanliness.

When you compare diamond sharpening stones to traditional stones, the benefits become even clearer. Diamond stones last 5–10 times longer than water or oil stones. You spend less time replacing stones and more time working. Sharpening is also 2–4 times faster, so you can keep your tools in top shape with less downtime.

Feature |

Diamond Sharpening Stones |

Traditional Stones |

|---|---|---|

Lifespan |

5–10 times longer |

Shorter lifespan |

Speed of sharpening |

2–4 times faster |

Slower |

Maintenance requirements |

Low |

High (requires flattening) |

Diamond stones remove steel quickly and maintain a flat surface throughout their lifespan. You do not need to flatten them, which saves you time and effort. Traditional stones wear unevenly and need regular maintenance. Diamond stones also cut faster, so you need fewer strokes to get a sharp edge. This efficiency is crucial for high-volume industrial woodworking.

Type of Stone |

Sharpening Speed |

Consistency |

|---|---|---|

Diamond Stones |

Fast |

Very consistent |

Water Stones |

Quick |

Moderate consistency |

Oil Stones |

Slow |

Less consistent |

When you select diamond sharpening stones for industrial use, you should focus on several important factors:

Diamond Type: Monocrystalline diamonds last longer, while polycrystalline types are more economical.

Bonding Method: Electroplated stones offer longer life. Resin bonded stones are also available.

Substrate Material: Steel substrates are durable. Aluminum is lighter. Always choose high-quality materials.

Grit Progression: Use a combination of grits, such as 400/1000, for versatility in sharpening.

Maintenance: Regular cleaning and care help your stones last for decades.

Tip: Choose stones that match your production needs. High-end tools benefit from premium stones with monocrystalline diamonds and electroplated bonds.

You can see that diamond sharpening stones meet the demands of Industrial Applications of Diamond Sharpening Stones. They offer speed, durability, and consistent results, making them the best choice for woodworking businesses that want to stay competitive.

Diamond sharpening stones use a layer of industrial diamond particles bonded to a flat surface. You get a tool that is harder than any steel used in woodworking. These stones cut quickly and stay flat, which helps you maintain sharp edges on your tools. You do not need oil for lubrication. Water works well and keeps your workspace clean. Many woodworking businesses choose diamond stones because they deliver reliable results for a wide range of tools.

Note: Diamond stones use either monocrystalline or polycrystalline diamonds. Monocrystalline diamonds last longer and provide consistent sharpening, making them ideal for demanding industrial environments.

You can find diamond stone sharpeners in seversal types and grit levels. Each grit size affects how much material you remove and the finish you achieve. Coarse grits shape and repair damaged edges. Fine and extra-fine grits refine and polish the edge. Some stones use resin bonding for a smoother feel, while others use electroplated bonds for durability.

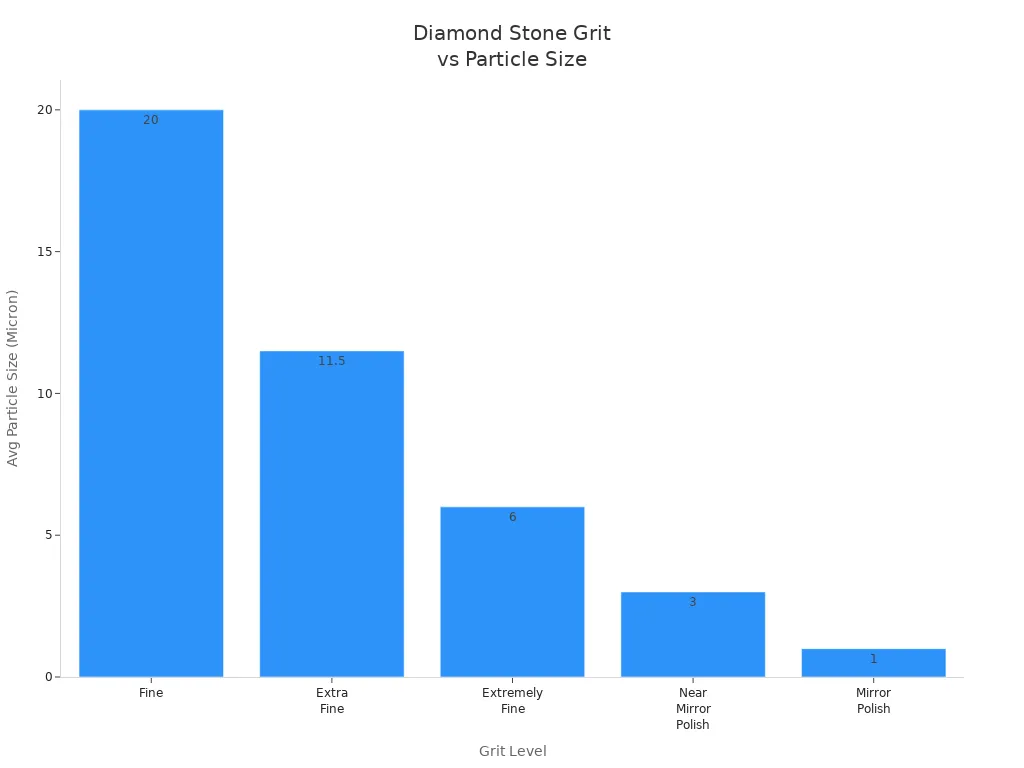

Here is a table that shows common grit levels and their uses:

Grit Level |

Description |

Particle Size |

Grit Range |

|---|---|---|---|

Fine |

Modest sharpening rate, frosted edge appearance |

15-25 Micron |

600 - 1000 |

Extra Fine |

Slow sharpening, edge starts to look polished |

8-15 Micron |

1000 - 2000 |

Extremely Fine |

Extremely sharp edge, very slow sharpening |

4-8 Micron |

2000 - 6000 |

Near Mirror Polish |

Edge is very near perfect |

2-4 Micron |

6000 - 10,000 |

Mirror Polish |

Sharpest edge, extremely slow sharpening |

0-2 Micron |

10,000+ |

You can select the right grit based on your sharpening needs. For most Industrial Applications of Diamond Sharpening Stones, you will use a progression from coarse to fine grits to achieve both speed and a razor-sharp finish.

Diamond sharpening stones offer impressive durability. You can expect them to last much longer than traditional stones, especially in professional or industrial settings. Here is a comparison of typical lifespans:

Type of Stone |

Typical Lifespan (Years) |

|---|---|

Diamond Stones |

5-10 (professional use) |

10-20 (hobbyist use) |

|

Several decades (occasional use) |

|

Traditional Stones |

Shorter lifespan, prone to wear |

To maximize the lifespan of your diamond stones, you should follow these maintenance practices:

Clean your tools before sharpening to prevent contamination.

Use water as a cutting fluid to keep the diamond surface clear.

Wipe the stone dry after use to prevent rust.

Store stones in a dry area to avoid corrosion.

Place leafing materials between stones to prevent abrasive sides from rubbing.

Avoid using excessive pressure during sharpening.

Use the entire surface of the stone to distribute wear evenly.

Regularly check for cleanliness and remove swarf buildup.

Tip: Consistent maintenance ensures your diamond stones deliver top performance for all your sharpening needs.

Diamond sharpening stones provide a reliable, long-lasting solution for woodworking businesses. You gain efficiency and precision, which are essential for the Industrial Applications of Diamond Sharpening Stones.

You rely on chisels and plane blades for precise woodworking. Diamond sharpening stones transform your sharpening process in industrial settings. These stones use industrial diamond particles to cut quickly and require minimal maintenance. You save time and keep your workflow efficient.

You sharpen a wide range of steels, including tough alloys like A-2 steel and carbide. Softer abrasives struggle with these materials, but diamond stones handle them with ease.

You benefit from a complete sharpening regimen. Diamond abrasives come in different grits and forms, so you can grind, polish, and strop your blades using one system.

You maintain a flat surface on your blades. Diamond stones are specifically designed to flatten chisels and plane blades, which enhances the efficiency of your sharpening process.

Tip: Use monocrystalline diamond stones for high-end tools. These stones last longer and deliver consistent results, even under heavy industrial use.

Diamond sharpening stones help you achieve razor-sharp edges and maintain blade flatness. You improve the quality of your woodworking and reduce tool replacement costs. The Industrial Applications of Diamond Sharpening Stones make your sharpening station more productive and reliable.

You need sharp saws and specialty tools for demanding woodworking tasks. Diamond stones offer unique advantages in industrial environments. Unlike water stones, diamond stones do not create mud that erodes tool edges. You get a true flat edge, which is essential for effective sharpening.

Diamond stones cut the quickest for shaping and initial honing. You spend less time sharpening and more time working. These stones maintain flatness and do not require frequent flattening, which is crucial when you sharpen many tools each day. Their hardness allows you to cut through various alloys more effectively than traditional stones.

You sharpen saw teeth and specialty blades with precision.

You avoid uneven wear and maintain consistent blade geometry.

You use diamond paste for polishing intricate or hard-to-reach areas.

Note: Premium diamond stones and diamond paste help you maintain high-end specialty tools, ensuring top performance in every project.

The Industrial Applications of Diamond Sharpening Stones extend to all your cutting tools. You keep your saws and specialty blades in optimal condition, supporting high-volume production and consistent results.

You manage large-scale tool maintenance in your woodworking business. Diamond sharpening stones provide unmatched durability and efficiency. High-quality synthetic diamonds ensure uniform sizes and strengths, making your sharpening tools tougher and more efficient under friction and pressure.

Resin bonded diamond stones last far longer than traditional sharpening stones. You reduce replacement costs and downtime.

The resin binder reduces blade wear during sharpening. It evenly distributes pressure and prevents over-grinding, preserving the blade's edge.

You use monocrystalline diamond stones for premium tools. These stones withstand heavy use and maintain their performance over time.

Diamond stones help you flatten and sharpen a wide range of tools quickly. You maintain the flatness of other sharpening stones, making your sharpening station more versatile. The Industrial Applications of Diamond Sharpening Stones support your business by streamlining maintenance, improving tool longevity, and boosting productivity.

Tip: Regularly clean and inspect your diamond stones. Consistent maintenance ensures reliable performance and extends the life of your sharpening equipment.

You gain a competitive edge by adopting diamond sharpening technology for large-scale maintenance. Your tools stay sharp, your processes run smoothly, and your business benefits from long-term savings.

You want a sharpening solution from a trusted source. HUAYIDA stands out as a leading manufacturer in the diamond sharpening stone industry. Established in 1992, Changzhou Huayida Tools Co., Ltd. has specialized in producing diamond tools and sharpening stones for over two decades. You benefit from their experience and commitment to quality. HUAYIDA exports products to Europe, North America, Japan, and Southeast Asia. Many woodworking businesses rely on HUAYIDA for consistent performance and reliability. The company’s reputation as a professional supplier gives you confidence in every purchase.

HUAYIDA’s long history and global reach show their dedication to innovation and customer satisfaction. You gain access to advanced sharpening technology designed for industrial needs.

You need sharpening stones that deliver results in demanding environments. HUAYIDA diamond sharpening stones use monocrystalline industrial diamonds. This feature gives you a longer life cycle and consistent sharpening performance. You can select custom grit combinations from 200 to 3000 grit. This flexibility lets you match the stone to your specific tools and workflow. HUAYIDA stones arrive ready to use. You do not need to flatten them before starting. The stones retain their flatness for years, so you spend less time on maintenance and more time on production.

Monocrystalline diamond particles provide superior hardness.

Custom grit options support a wide range of sharpening tasks.

Ready-to-use plates save you setup time.

Flatness retention ensures precise results.

You improve efficiency and reduce costs by choosing stones that require minimal upkeep. HUAYIDA’s product features help you maintain high standards in your woodworking business.

You want to select the right sharpening stones for your industrial woodworking shop. HUAYIDA offers several products tailored to your needs. The following table highlights key strengths and recommended options:

Key Strengths of HUAYIDA |

Description |

|---|---|

Durability |

Utilizes monocrystalline industrial diamonds for extended life cycle. |

Custom Grit Combinations |

Offers custom grit combinations (200–3000 grit range) tailored to industrial users. |

Low Maintenance |

Ready-to-use diamond plates that retain flatness for years, unlike traditional waterstones. |

You can choose HUAYIDA’s premium diamond plates for heavy-duty sharpening. These plates work well for chisels, plane blades, and specialty tools. You also benefit from resin bonded stones for large-scale maintenance. Custom grit combinations let you optimize your sharpening process for different tool steels and edge requirements.

HUAYIDA products give you the reliability and performance you need to keep your woodworking business running smoothly. You invest in quality and efficiency with every purchase.

You start the sharpening process with grinding and shaping. This step restores the edge and corrects any damage. Diamond sharpening stones use industrial-grade diamonds, which give you fast cutting and less maintenance than traditional stones. You can handle dull tools and repair nicks with coarser grits.

Choosing the right grit is important for effective grinding. You use coarse grits, such as 200 or 400, to remove material quickly and reshape the edge. Medium grits, like 600 or 1000, refine the edge and prepare it for finishing. Fine grits, above 2000, polish the edge and create a smooth finish.

Grit Level |

Purpose |

Typical Use Case |

|---|---|---|

Coarse |

Rapid material removal |

Dull or damaged tools |

Medium |

Edge refinement |

Regular maintenance |

Fine |

Polishing |

Final finishing |

Tip: Begin with the coarsest grit needed for your tool’s condition. Progress to finer grits for a sharper, smoother edge.

You remove material by holding your tool at the correct angle and applying consistent pressure. Secure your diamond stone on a stable surface. Move your tool across the stone in smooth strokes. Diamond stones cut efficiently, so you do not need to press hard. You achieve a flat, even edge with fewer passes.

Use steady, controlled movements.

Cover the entire surface of the stone to distribute wear.

Check your progress often to avoid over-grinding.

You need to maintain the correct angle and flatness during sharpening. This step ensures your tools perform accurately in industrial woodworking.

Holding the right angle is key to a sharp edge. For most woodworking tools, you use angles between 25 and 30 degrees. You can use angle guides or visual markers to help. Consistent angles prevent uneven edges and improve cutting performance.

Note: Secure your stone and tool before sharpening. This helps you maintain the correct angle throughout the process.

You may encounter some common mistakes during truing and flattening:

Using too much pressure, which can damage the diamond surface.

Failing to clean the stone, leading to clogged grit and poor results.

Not checking the angle, which causes uneven sharpening.

Over-grinding, which shortens tool life.

You avoid these mistakes by using light pressure, cleaning your stone regularly, and checking your angle often.

You finish the sharpening process by polishing the edge. This step creates a razor-sharp finish and prepares your tool for use.

You use fine and extra-fine diamond stones to polish the edge. Light pressure and smooth strokes help you achieve a mirror-like finish. Clean your stone after each use to remove metal slurry and keep the diamond surface effective.

You inspect your tool after polishing. Look for a consistent, sharp edge. Check for any signs of rust or wear. Dry your tool immediately and apply a thin layer of oil to prevent corrosion. Store your tools in a dry, well-ventilated area.

Regular inspection and maintenance keep your tools in top condition and extend their lifespan.

Stropping is the final step in your sharpening process. You use stropping to refine and polish the edge of your woodworking tools after sharpening and honing. This step removes any remaining burrs and creates a razor-sharp, mirror-like finish. Stropping helps you achieve the highest level of sharpness, which is essential for precise and clean cuts in industrial woodworking.

You can use a strop made from leather, canvas, or synthetic materials. Many professionals apply a fine abrasive compound or diamond paste to the strop. This compound further polishes the edge and enhances sharpness. For industrial applications, diamond paste works especially well because it matches the hardness of your diamond sharpening stones and delivers consistent results.

Why Stropping Matters in Industrial Woodworking

You extend the life of your tools by maintaining a keen edge.

You reduce the frequency of major sharpening sessions.

You improve the quality of your finished products with cleaner cuts.

You save time and money by minimizing tool wear.

Tip: Stropping is not just for knives. You should strop chisels, plane blades, carving tools, and even specialty cutters to maintain peak performance.

How to Strop Your Tools

Secure your strop on a flat, stable surface.

Apply a small amount of diamond paste or stropping compound if needed.

Hold your tool at the same angle used during sharpening.

Draw the edge lightly across the strop, moving away from the cutting edge.

Repeat this motion several times on each side of the blade.

Use gentle pressure. Let the strop and compound do the work.

You should inspect the edge after stropping. Look for a smooth, polished surface with no visible burrs. A properly stropped edge will feel extremely sharp and glide easily through wood.

Best Practices for Industrial Settings

Assign a dedicated stropping station in your sharpening area.

Clean your strop regularly to remove metal particles.

Replace or recondition the strop when it shows signs of wear.

Train your team on proper stropping techniques to ensure consistency.

Note: Consistent stropping as part of your maintenance routine keeps your tools in optimal condition and supports high productivity in your woodworking business.

Stropping completes your sharpening workflow. You gain sharper tools, better results, and a more efficient operation. This simple step can make a significant difference in your industrial woodworking processes.

A well-organized sharpening station helps you work efficiently and safely. You should dedicate a specific area in your workshop for sharpening tasks. This keeps your workflow smooth and prevents cross-contamination with other processes.

Set up three diamond plates: coarse, fine, and super fine. This allows you to handle everything from heavy grinding to final polishing.

Keep a strop nearby to finish edges and maintain sharpness between major sharpening sessions.

Use stable, non-slip surfaces for your stones and tools. This reduces accidents and improves accuracy.

Store all sharpening supplies within easy reach. You save time and keep your workspace tidy.

Tip: Label each diamond plate by grit. This helps you and your team select the right stone quickly.

You protect yourself and your team by following safety and ergonomic guidelines. Proper setup and habits reduce fatigue and prevent injuries.

Wear safety glasses to shield your eyes from metal particles.

Use gloves if you handle sharp tools or clean stones.

Position your sharpening station at a comfortable height. This prevents back and wrist strain.

Stand on an anti-fatigue mat if you sharpen tools for long periods.

Keep your workspace well-lit. Good lighting helps you see tool edges clearly and avoid mistakes.

Note: Encourage regular breaks during long sharpening sessions. This keeps you alert and reduces the risk of repetitive strain injuries.

Regular maintenance keeps your diamond sharpening stones performing at their best. You extend their lifespan and ensure consistent results by following a few simple routines.

Clean your tool before sharpening. Dirt and grime can contaminate the diamond surface.

Use water as a cutting fluid. Rinse away metal particles to keep the stone clear and effective.

Wipe the stone dry after each use. Add a few drops of water, then use a rag or paper towel to remove moisture.

Store your stones in a dry area. This prevents rust and corrosion.

Place paper towels, cloth, or plastic bags between stones. This stops abrasive surfaces from rubbing together and causing damage.

Consistent care for your diamond stones means you spend less time on maintenance and more time producing quality work.

By following these best practices, you create a safer, more efficient, and longer-lasting sharpening environment for your woodworking business. Your tools stay sharp, your team works comfortably, and your operation runs smoothly.

You want to make smart investments for your woodworking business. Diamond sharpening stones help you save money over time. Traditional sharpening stones often seem cheaper at first. You might pay about $40 for one stone. However, you need to replace it every year. Over ten years, you spend $400 on replacements.

Diamond sharpening stones cost more up front. You might pay $150 for a high-quality diamond stone. This stone can last up to ten years with proper care. You only spend $150 in that same decade. This means you save about 62.5% compared to traditional stones.

Traditional stones: $40 per year × 10 years = $400 total

Diamond stones: $150 one-time cost for 10 years

Total savings: $250 over ten years

Investing in diamond sharpening stones reduces your long-term costs. You keep more money in your business for other important needs.

You want your team to work efficiently. Diamond sharpening stones help you sharpen tools faster. You do not need to flatten these stones often. You also spend less time cleaning up, since water is the only fluid you need. Your team can sharpen more tools in less time.

Diamond stones keep their flatness. This means you get consistent results every time. You avoid mistakes that come from uneven sharpening. Your tools stay sharp longer, so you spend less time on maintenance and more time on production.

Benefit |

Impact on Productivity |

|---|---|

Faster sharpening |

More tools ready for use |

Less maintenance |

Fewer interruptions |

Consistent flatness |

Higher quality work |

Longer tool life |

Fewer replacements needed |

When you use diamond sharpening stones, you boost your shop’s output and keep your workflow smooth.

Many woodworking businesses have switched to diamond sharpening stones and seen strong results. For example, a mid-sized furniture manufacturer replaced all traditional stones with diamond plates. The company reduced sharpening time by 50%. Workers spent less time waiting for tools and more time building products.

A cabinet shop owner reported that diamond stones lasted much longer than expected. The shop saved hundreds of dollars in replacement costs over five years. The team also noticed fewer tool failures and better edge quality.

You can see similar results in your own business. When you invest in diamond sharpening stones, you gain both financial and operational advantages. Your tools stay sharp, your team works faster, and your bottom line improves.

Choosing diamond sharpening stones is a smart move for any woodworking business that values efficiency and long-term savings.

Diamond sharpening stones give you faster sharpening, longer tool life, and consistent results. You outpace traditional stones in every key area. If you want to boost productivity and reduce costs, consider upgrading your sharpening process.

Ready to improve your woodworking business? Contact HUAYIDA for expert advice and the best diamond sharpening solutions for your needs.

Diamond sharpening stones use industrial-grade diamonds. You get faster sharpening, longer stone life, and consistent flatness. These features help you maintain high productivity and tool quality in your woodworking business.

You should match the grit to your sharpening task. Use coarse grits for repairing damaged edges. Select medium grits for regular sharpening. Choose fine grits for polishing and finishing. Progress through grits for the sharpest results.

You can use water as a lubricant. Water keeps the stone clean and cool. You do not need oil. Water is safer and easier to clean up in industrial settings.

HUAYIDA diamond sharpening stones last for years with proper care. Monocrystalline diamonds and quality bonding ensure long service life. You can expect reliable performance even with frequent industrial use.

You can sharpen chisels, plane blades, saws, carving tools, and specialty cutters. Diamond stones work well on high-alloy and carbide tools. You get sharp, precise edges for all your woodworking needs.

Clean your stones after each use. Use water to rinse away metal particles. Dry the stones before storage. Store them in a dry place. Avoid excessive pressure during sharpening to extend stone life.

Yes, HUAYIDA diamond stones meet the demands of industrial woodworking. You benefit from fast sharpening, minimal maintenance, and long-lasting durability. These features support high-volume production and consistent tool quality.

content is empty!

Contact Us