Views: 0 Author: Aisha Publish Time: 2025-10-21 Origin: Site

If you’ve ever been on a jobsite where blades and scrapers go dull mid-job, you know the small things add up fast. One dull blade can mean ruined cuts, slower progress, and frustration that ripples through the crew. That’s why portable diamond sharpening solutions are a quiet superpower for construction teams — they get workers back to cutting with confidence without sending tools offsite.

Jobsites are dusty, rough, and unpredictable. Tools take a beating: edges nick on screws, concrete dust grinds away sharpness, and the pace of work doesn’t afford detours to the shop. Portable sharpeners bring precision back to the toolbelt. They’re fast, robust, and built to live in a hard hat box alongside the tape measure and driver.

I’m part of the HUAYIDA team — we design, test, and manufacture diamond sharpening solutions that balance performance with real-world durability. We make everything from wallet-size card sharpeners to modular kits for professional shops. My job is to understand how our products perform in the field, and then help translate that into guidance that crews can actually use.

I’ve been on jobsites and in workshops; I know how a simple, sharp tool changes the whole day. There’s a practical joy in handing a worker a compact HUAYIDA sharpener that brings a chisel or utility knife back to life in minutes. It’s one of those small efficiencies that compounds into big wins: faster cuts, less rework, safer crews.

A portable diamond sharpener is a compact abrasive tool that uses industrial diamond grit bonded to a substrate. Unlike bulky bench stones or whetstones that demand a stable bench, portable diamond sharpeners are designed for travel, rough handling, and rapid on-site use.

Diamond abrasive layer — microns vary (coarse to fine).

Substrate — metal or polymer backing for strength.

Grip or housing — rubberized or plastic frame for handling.

Mounting options — magnets, velcro, or a simple clamp for jobsite setup.

Credit-card sized (84×50×1.6 mm) — pocket-ready for quick touch-ups.

Small bench/hand tools (100×40×6 mm) — better leverage for blades and chisels.

Modular kits — interchangeable grit plates and carrying cases.

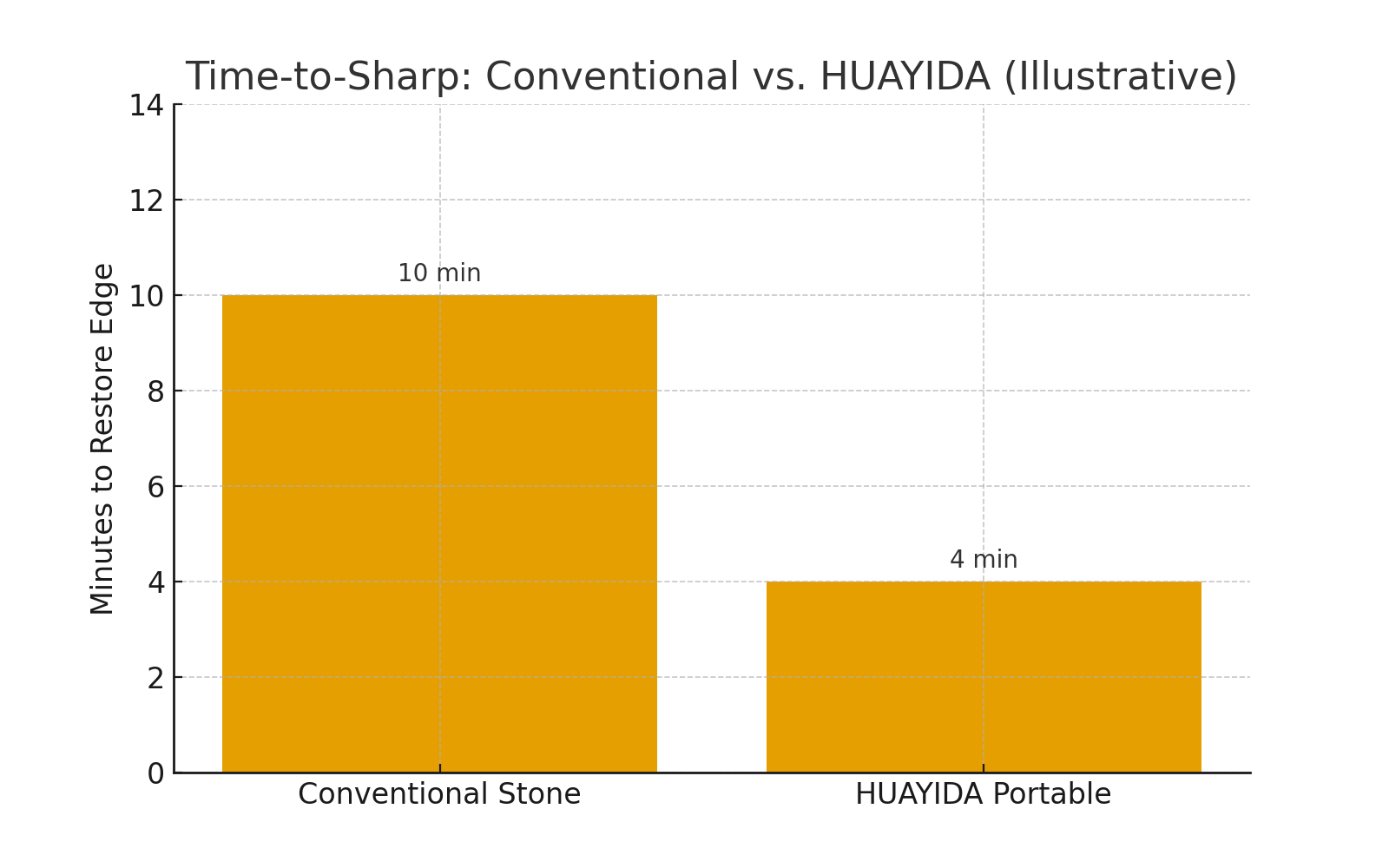

Diamond abrasives cut fast. That means a dull utility knife can be back to a factory edge in minutes — not hours. On a busy day, those minutes matter.

Diamond surfaces stay flat and aggressive over long use. That consistency preserves the tool’s geometry and extends usable life, reducing replacements.

Sharp tools are safer — they require less force and provide more control. Fewer slips, fewer mistakes. That’s a direct productivity and safety benefit for any crew.

I’ll walk you through the HUAYIDA tools I trust and recommend for real-world construction use.

What it is: Credit-card sized sharpener with micronized monocrystalline diamond on one side.

Use case: Utility knives, thin blades, quick touch-ups.

Why it works: Durable, compact, fits in a wallet or tool pouch — perfect for foremen and finishers who need a tiny lifeline for blades.

What it is: A small hand stone with a thicker substrate and non-slip backing.

Use case: Wood chisels, plane irons, drywall knives.

Why it works: Offers more leverage for heavier tools while still remaining portable enough to be carried in a job box.

What it is: A carry case with multiple grit plates (coarse, medium, fine) and mounting options.

Use case: Teams that want an on-site sharpening station — trade crews, jobsite lead kits.

Why it works: Replaceable plates mean less waste and more flexibility: rough shaping then fine honing without leaving the site.

Choosing isn’t only about grit size — it’s about matching the tool, the crew’s workflow, and the jobsite environment.

Coarse (e.g., 120–320 grit) for reshaping and removing nicks.

Medium (e.g., 400–600 grit) for general-purpose sharpening.

Fine (e.g., 800–1000+ grit) for polishing and fine edges.

If your crew uses utility knives and scrapers, a pocket card plus a medium bench stone covers most bases.

If your site is heavy on dust and moisture, choose models with sealed backings and non-slip grips. HUAYIDA’s jobsite stones use sealed substrates and rubber edges to withstand rough handling.

Look for stones with:

Secure grips so workers can sharpen while standing.

A simple clamp or magnetic base to stabilise the stone when needed.

Compact carry cases to keep grit plates clean.

Let’s put these tools into actual trades and moments you’ll recognize.

Chisels and plane irons go dull fast when ripping through treated lumber. A quick reshaping with a coarse diamond plate restores cutting geometry so timbers square neatly and cuts fit first time.

Drywall knives and scrapers need razor edges for clean seams. The pocket card is perfect for quick touch-ups between sheets — less mud on the blade, no ragged edges.

Tile cutters, scrapers, and some masonry chisels benefit from harder abrasives. A robust jobsite bench sharpener paired with water-resistant housings helps maintain tools exposed to cement and grit.

Great performance depends on how the stone is treated in the field. Here are practical, no-nonsense tips I give crews.

Use a stiff nylon brush to knock off metal swarf and grit.

For sticky residues, a splash of water and brushing usually does the trick. Avoid harsh solvents that can damage bonding agents and complicate disposal.

Water or a light, water-based lube is usually enough for diamonds.

Keep lubricant use minimal to reduce runoff on site — capture rinse water where possible.

Keep stones in cases or wrapped in cloth to prevent knocks.

Store flat — don’t wedge them where they can bend or warp.

Sharpening on-site introduces hazards if done carelessly. I insist crews take simple safety steps.

Gloves (cut-resistant) and eye protection are non-negotiable.

Stabilize the tool — secure with a clamp or use a non-slip surface to avoid slippage that leads to cuts.

Brush rather than blow the dust; use local capture when possible.

Collect metal filings in a designated container; dispose according to your local regulations.

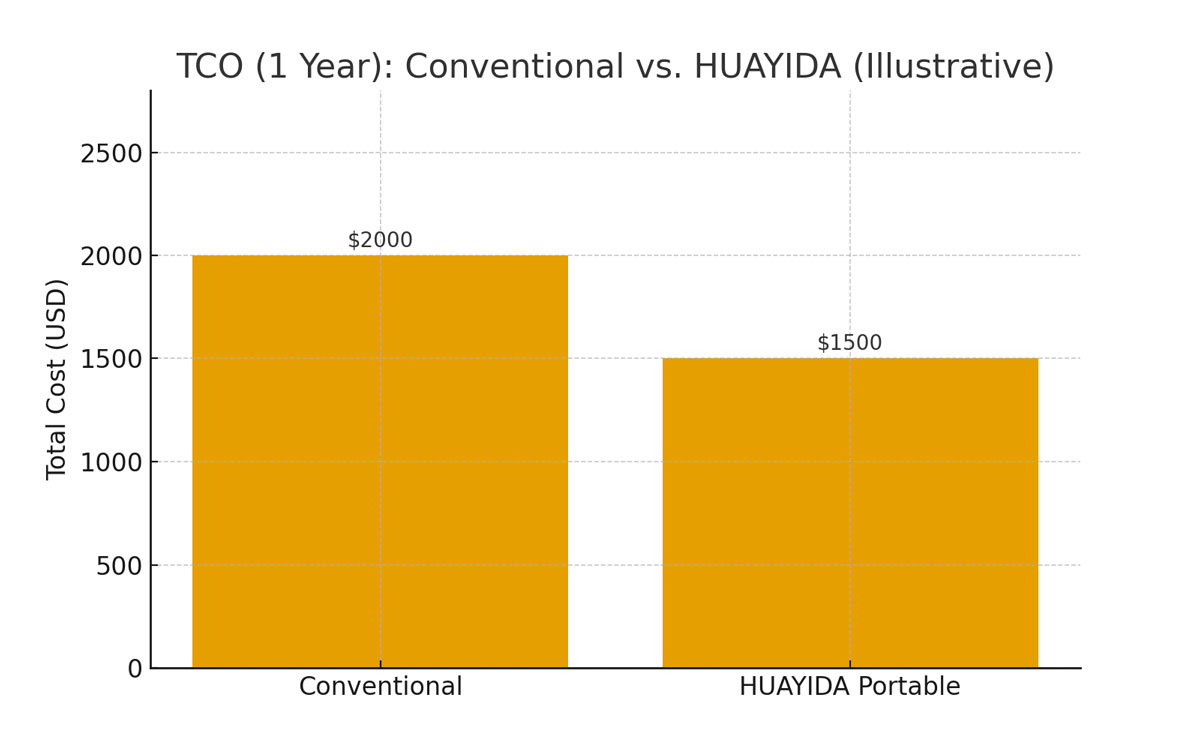

You’ll hear “cheap tool” vs “expensive” debate a lot. Let’s look at the math simply.

A high-quality HUAYIDA portable sharpener might cost more than a throwaway stone, but because it lasts longer and keeps tools performing, crews typically see lower tool replacement costs and less downtime.

When a blade stays sharper, cuts go faster and replacements drop. That’s measurable: less idle time, fewer emergency trips to the shop, and smoother project flow.

Last fall I visited a four-person framing crew that was losing time to dull blades — a full hour a day, they estimated, between swapping knives and re-cutting.

We supplied each carpenter with a HUAYIDA Pocket Card and placed a HUAYIDA Jobsite Bench in the trailer. I trained them on quick maintenance routines and storage.

Within two weeks:

The crew reported faster cuts and fewer replacement blades.

One foreman told me they reclaimed roughly 45 minutes of productive work per day.

Blade replacement costs dropped by about 30% in the first month.

That’s the practical payoff: small tools, big results.

Portable sharpeners aren’t just convenient — they can be a greener choice.

Because diamond stones last longer, fewer stones and fewer blades end up in the landfill. For large contractors, that’s meaningful volume over a year.

Portable solutions cut trips to the shop. Fewer vehicle runs, fewer returns — less fuel burned and more time on the tools.

How often should crews touch up blades? Quick touches every few hours of heavy use keep edges functional; a full re-sharpen depends on the tool and work (coarse work needs coarser reshaping).

Are pocket cards safe to carry? Yes, store them in a case or plastic sleeve to avoid accidental contact.

Can diamonds handle masonry tools? For light masonry touch-ups yes; for heavy re-profiling you’ll need larger, more robust bench solutions or grinders.

Do diamond stones clog? They can accumulate metal swarf; regular brushing prevents glazing and maintains cutting activity.

What about resharpening carbide? Carbide needs specialized diamond abrasives and often a different technique; check HUAYIDA’s carbide-specific products for that use.

Portable diamond sharpeners are a straightforward, high-impact investment for on-site construction teams. They reduce downtime, improve safety, and extend tool life — and when you factor in total cost and environmental impact, they’re often the smarter choice. I’ve seen the difference on jobsites: when crews have a HUAYIDA sharpener within reach, work flows better, edges last longer, and morale improves (seriously — a sharp blade makes people smile). If you manage crews, set up procurement, or just carry the bag, put a portable diamond sharpener on your checklist. You’ll wonder how you ever worked without one.

Q1: What grit combinations should a small crew carry to cover most on-site needs?

A: I recommend a two-plate strategy: one coarse (300–400) to restore edges and remove nicks, and one medium/fine (1000–1200) to refine and polish. Add a pen or pocket sharpener for small touch-ups.

Q2: How often do HUAYIDA diamond plates need replacing?

A: Life depends on usage, but our plates are built for longevity. Under normal field use, expect months to years. Replace when sharpening time increases noticeably or the diamond surface becomes irregular despite cleaning.

Q3: Can diamond sharpeners work on carbide-tipped blades?

A: Yes — diamond abrasives are among the few abrasives that can abrade or true carbide edges. Use light strokes and appropriate grit to avoid overheating the carbide tip.

Q4: Are HUAYIDA portable sharpeners safe to use in wet environments?

A: Diamond surfaces themselves are corrosion-resistant, but housing, adhesives, and fasteners matter. Our portable kits are built with corrosion-resistant materials, but always dry and store plates after heavy exposure to salt or chemical contaminants to prolong life.

Q5: Do you offer training or guidelines for crews new to diamond sharpening?

A: Yes — we provide simple angle charts, grit recommendations, and short workflows for common tools. Tell us your tool list and we’ll recommend a step-by-step routine your foremen can use.

Contact Us