Views: 0 Author: Aisha Publish Time: 2025-10-27 Origin: Site

Choosing the right Diamond Sharpening Stones for medical and precision cutting tools matters a lot. I have seen how the wrong choice can lead to edge failure or even tool contamination. I always pay close attention to grit size, durability, contamination control, and compliance with industry standards. Each factor protects tool performance and patient safety.

Choose the right grit size for your tools. Coarse grits reshape edges, while fine grits polish them. Match the grit to the tool's material for best results.

Prioritize contamination control. Always sharpen in a clean environment and store stones properly to ensure patient safety and tool effectiveness.

Select the appropriate bond type for your sharpening stones. Vitrified stones offer heat resistance, while resin stones provide a smooth finish. Choose based on your specific application needs.

Maintain flatness for consistent sharpening. A flat stone ensures even edges, especially for straight tools. Regularly check and clean your stones to keep them effective.

Verify supplier certifications. Look for ISO 13485 and compliance with FDA or CE standards to ensure the quality and safety of your sharpening stones.

When I select Diamond Sharpening Stones for medical and precision cutting tools, I always focus on edge retention. The bond matrix in these stones holds the diamond grit in place. If the bond is balanced, the diamond particles get released at the right time. This keeps the cutting edge sharp and efficient. I have learned that a harder bond holds diamonds longer, which works well for softer tool materials. A softer bond releases diamonds faster, which is better for harder materials. When the bond exposes the diamond crystals evenly, I see faster cutting, smoother cuts, and less heat. This helps reduce chipping and keeps the tool edge in top shape.

A smooth surface finish is critical for medical and precision tools. I know that the right Diamond Sharpening Stones can create a fine, even edge. This is important because a rough or uneven finish can cause problems during use. For example, in surgery, a rough edge can damage tissue or slow down the procedure. I always match the grit size of the stone to the tool’s needs. Finer grits produce a polished edge, while coarser grits remove material quickly. I check the finish under magnification to make sure it meets strict standards.

Contamination control is a top priority in medical settings. I follow strict measures to keep tools and stones clean:

I always sharpen in a clean environment.

I use only clean equipment and materials.

I store Diamond Sharpening Stones in sealed containers when not in use.

Note: Even a small amount of contamination can put patient safety at risk. I never skip cleaning steps.

By focusing on these performance needs, I make sure that every tool I sharpen is safe, effective, and ready for critical work.

I always start by looking at grit size and consistency when I choose Diamond Sharpening Stones for medical and precision tools. Grit size ranges from coarse (around 120) to ultra-fine (up to 8000). Coarse grits remove material quickly and work well for reshaping or repairing damaged edges. Fine grits polish and refine the edge, which is essential for surgical instruments and precision blades.

Grit consistency matters just as much as grit size. If the grit is not uniform, sharpening results become unpredictable. I have seen uneven edges and poor finishes when the grit size varies across the stone. Consistent grit helps me avoid over-sharpening or under-sharpening. It also lets me master grit progression, which is important for both beginners and experienced sharpeners.

Grit size consistency is essential for effective sharpening of precision cutting tools.

Proper grit selection prevents issues like over-sharpening or under-sharpening, which can result in uneven edges.

Mastery of grit progression is crucial for both novices and experienced sharpeners to achieve optimal sharpness and maintain tool integrity.

I always match the grit to the tool and application. For example, I use a medium grit for general sharpening and a fine grit for finishing surgical tools. This approach gives me the best results and keeps the tool edge in top condition.

The way Diamond Sharpening Stones are bonded and constructed affects their performance and durability. I pay close attention to the bond type because it changes how the stone behaves during sharpening. Here is a comparison of the main bond types:

Bond Type | Advantages | Applications | Limitations |

|---|---|---|---|

Vitrified | Excellent heat resistance, low grinding force, superior shape retention | Precision grinding of hard and brittle materials | Not suitable for flexible grinding; more brittle |

Resin | Smooth surface finish, self-sharpening properties, lower cost | General-purpose grinding, including carbide tools | Lower thermal resistance and shorter lifespan |

Metal | Long life, excellent form-holding, high material removal rate | Grinding hard materials like sapphire, ceramics | Generates more heat and may require dressing |

I often choose vitrified stones for premium applications. They offer excellent heat resistance and keep their shape well, which is important for precision work. Resin-bonded stones give a smooth finish and cost less, but they do not last as long. Metal-bonded stones last the longest and work well on very hard materials, but they can generate more heat.

Construction also matters. I look for stones made with monocrystalline diamonds bonded through an electroless process. These stones use a precision ground nickel carbon steel base. This construction keeps the stone flat and prevents it from dishing or grooving. The sharpening surface stays consistent, which is critical for precision tools.

The exceptional hardness of diamond particles enhances sharpening precision and speed.

A continuous diamond surface prevents diamond and nickel lift, improving anti-corrosion.

Double-sided stones offer versatility with two grit sizes for coarse and fine sharpening.

Flatness is a key factor when I sharpen tools with straight edges, like chisels or scalpels. A flat stone ensures the edge stays even and sharp. For curved blades, such as some surgical knives, perfect flatness is less critical because only a small part of the edge touches the stone at any time.

Flatness matters (up to a point) when you are sharpening a tool with a straight cutting edge like a chisel, but many knife blades have a bit of curve to the edge. With a curved edge you will only have a single point of contact between the edge and the stone. Any stone that looks flat is probably flat enough for knife sharpening.

From my experience, Diamond Sharpening Stones stay flatter than most other stones, except for freshly lapped waterstones. This flatness usually lasts longer, which helps me maintain a consistent sharpening angle and edge quality.

From my experience diamond hones have been flatter than most everything except a freshly lapped waterstone though that flatness is usually long gone before the sharpening is done. Holding a tight angle when hand sharpening is not that important, getting the apex to meet perfectly and removing the burr is.

I always select the size and shape of the stone based on the tool I need to sharpen. Large, flat stones work best for long, straight blades. Small or narrow stones fit well with fine instruments or tools with tight curves. Some applications require specialty shapes, like tapered or round stones, to reach difficult areas.

I also consider double-sided stones for versatility. These stones let me switch between coarse and fine grits without changing tools. This saves time and ensures I always have the right grit for each step.

When I specify Diamond Sharpening Stones, I look for the right combination of grit size, bond type, flatness, and shape. This approach helps me achieve the best results for medical and precision cutting tools.

I often work with stainless steel tools in medical and precision settings. Stainless steel resists corrosion and holds a sharp edge well. I choose diamond sharpening stones with medium to fine grit for these tools. Medium grit (around 600–1000) helps me restore a dull edge quickly. Fine grit (1200–2000) lets me polish the edge to a mirror finish. I prefer monocrystalline diamond stones because they last longer and sharpen more efficiently. Stainless steel responds well to diamond abrasives, so I get a clean, precise edge every time.

Carbide and ceramic tools present a different challenge. These materials are much harder than stainless steel. Traditional sharpening stones struggle with them, but diamond stones excel. Diamonds rate a 10 on the Mohs hardness scale, so they grind even the toughest materials with ease. I always look for monocrystalline diamonds for better durability. Polycrystalline stones wear down too fast for my needs.

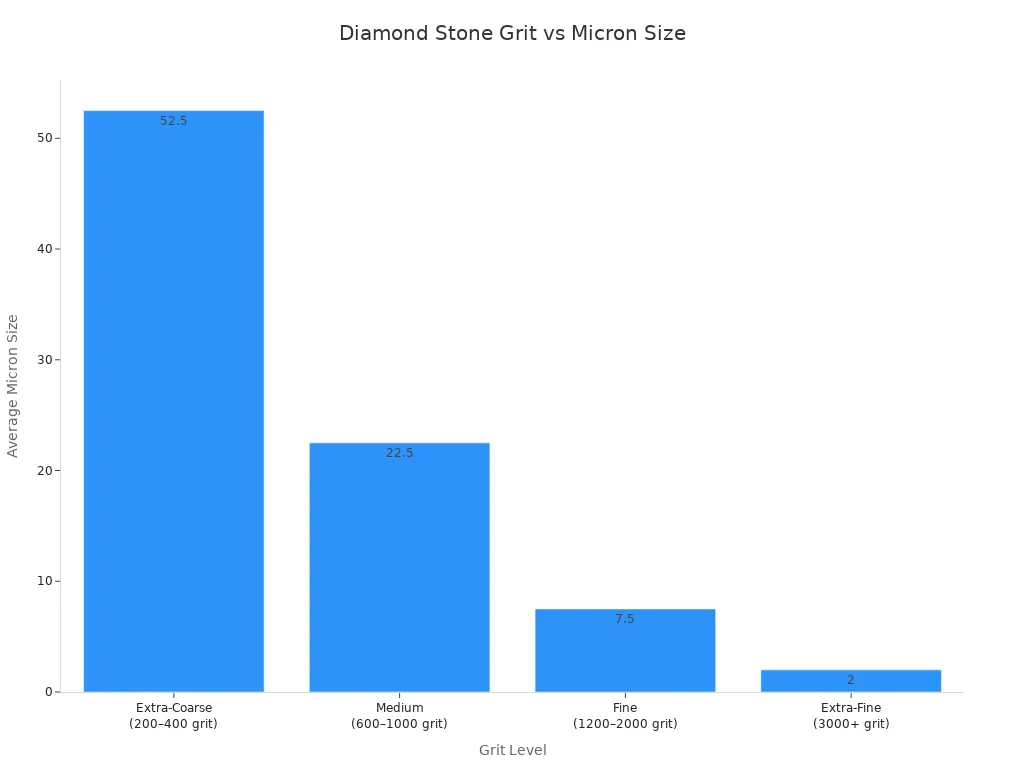

Here is a quick guide I use for selecting the right diamond stone for carbide and ceramic tools:

Micron Size | Best Use Case | |

|---|---|---|

Extra-Coarse (200–400) | 60–45 µm | Repair chips, reshape edges |

Medium (600–1000) | 30–15 µm | Regular sharpening, maintenance |

Fine (1200–2000) | 9–6 µm | Razor-sharp kitchen knives |

Extra-Fine (3000+ grit) | 3–1 µm | High-end Japanese knives, polishing |

I recommend a dual-grit 600/1200 plate for most sharpening needs.

Monocrystalline diamonds give me better results and longer life.

I always match the sharpening stone to the specific application. Each field has unique requirements. Medical device manufacturing often uses hard and brittle materials. I rely on diamond stones for precise shaping and a smooth surface finish. Surgical instruments need high precision. I use diamond stones to minimize friction and wear. Dental applications require intricate shapes and biocompatibility. Diamond stones help me create fine details for implants and crowns.

Application Area | Material Characteristics | Importance of Diamond Stones |

|---|---|---|

Medical Device Manufacturing | Hard and brittle materials (ceramics, metals) | Essential for precision and surface finish in implants and instruments |

Surgical Instruments | High precision required | Used for shaping and finishing to minimize friction and wear |

Dental Applications | Intricate shapes and biocompatibility | Critical for creating dental implants and crowns |

Tip: Always match the stone’s grit and construction to both the tool material and the application. This ensures the best results and extends tool life.

As someone who works at HUAYIDA, I have seen our dedication to quality and innovation every day. Our company has focused on diamond sharpening stones for medical and precision applications since 1993. Over the past 28 years, we have built a reputation for expertise and reliability.

We design our stones with a high density of diamonds per square centimeter. Each stone has an even distribution of diamonds, which gives consistent sharpening results. I always check for flatness because our stones stay completely flat, which sets us apart from imitations.

Note: HUAYIDA always aims to meet the changing needs of our customers. We offer OEM and ODM services, and we provide free samples to help clients find the best solution for their tools.

I often recommend our diamond sharpening stones to clients in the medical and precision tool industries. Here are some of our top picks:

HUAYIDA Vitrified Diamond Sharpening Stone

I use this stone for surgical instruments and fine cutting tools. It offers excellent heat resistance and keeps its shape, which is important for precise sharpening.

HUAYIDA Double-Sided Diamond Plate (600/1200 grit)

This plate works well for both stainless steel and carbide tools. The dual grit lets me switch between coarse and fine sharpening without changing stones.

HUAYIDA Diamond Needle Files

These files help me sharpen small or intricate tools, such as dental instruments or micro-surgical blades. The fine diamond coating ensures a smooth finish.

I trust these products because they deliver reliable results and meet strict industry standards. When clients need custom solutions, I work with our team to develop stones that fit their exact requirements. HUAYIDA’s commitment to quality and customer satisfaction makes us a trusted partner for medical and precision tool sharpening.

When I select diamond sharpening stones for medical and precision tools, I always check for the right certifications. These stones must meet strict quality standards. I look for ISO 13485 certification, which shows the supplier follows medical device quality management. I also check for compliance with FDA or CE requirements, depending on where the tools will be used. These certifications give me confidence that the stones are safe and reliable for critical applications.

Proper maintenance keeps my diamond sharpening stones working at their best. After each use, I clean the stone to remove metal particles. If I skip this step, the surface can clog and lose effectiveness. Here is how I clean and sterilize my stones in medical settings:

I scrub the sharpening surface with a stiff, plastic-bristled brush to remove debris.

I rinse the stone under running water or use an ultrasonic bath for a deeper clean.

I place the clean stone in a sterilization pouch with other instruments.

I run the pouch through an autoclave at 121°C for 30 minutes or 132°C for 4 minutes.

Regular cleaning and sterilization help extend the life of my stones and keep them safe for use on medical tools.

I always choose suppliers who meet high standards for quality and support. Here are the key things I look for:

Criteria | Description |

|---|---|

Accuracy of Grit Sizes | Grit sizes must match international standards within +/- 11%. |

Construction Method | Diamonds should be electroplated onto a precision ground base for flatness. |

Documentation & Support | Suppliers should offer technical training, custom solutions, and a risk-free trial for professionals. |

Maintenance of Design | Stones must help maintain the original design of the instruments during sharpening. |

Tip: I always ask for documentation and training from my supplier. Good support helps me get the best results and avoid costly mistakes.

By focusing on certifications, proper maintenance, and reliable suppliers, I make sure my sharpening process meets the highest standards for medical and precision tools.

When I specify diamond sharpening stones for medical and precision tools, I follow these steps:

I secure the stone on a stable surface.

I choose the correct sharpening angle for each tool.

I use a steady technique with consistent pressure.

I progress from coarse to fine grits for a polished edge.

I finish with a strop for maximum sharpness.

Matching stone specs to tool material and application always matters. I prioritize certified quality and supplier support.

For best results, I recommend consulting trusted suppliers or experts before making a final selection.

I look at the tool’s material and the sharpness I need. Coarse grits (120–400) fix damaged edges. Medium grits (600–1000) handle regular sharpening. Fine grits (1200+) polish and finish. I always match grit to the job.

Yes, I sterilize my stones in an autoclave after cleaning. I use a sterilization pouch and follow standard temperature and time settings. This keeps the stones safe for medical environments.

Diamond is the hardest known material. I use diamond stones because they cut through carbide, ceramics, and stainless steel quickly. Other stones wear out or fail to sharpen these tough materials.

I clean my stones after each use. I scrub with a plastic brush and rinse under water. For deep cleaning, I use an ultrasonic bath. Regular care keeps the surface

effective and extends the stone's life.

Contact Us